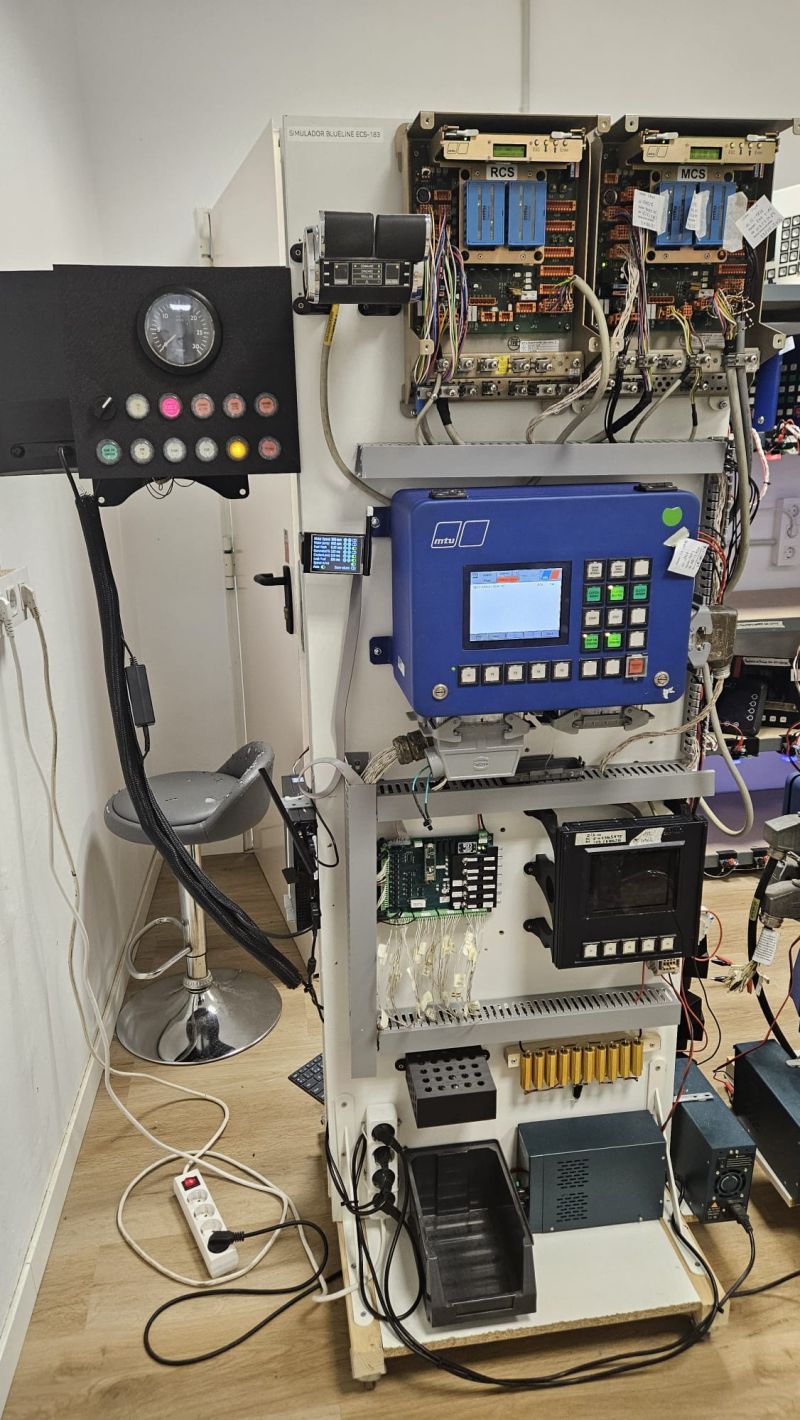

This is an example of our portable simulators, in this case we are looking at the simulation of a MTU 183 series engine system, using a

BlueLine ECS-183. The main feature is that this engine carries an injection pump, which we simulate in our simulator, just like the position

of the pump, in order to simulate an engine start-up by making the electronic system believe that it is working and controlling a real engine, with the

simulation of sensors for pressure, RPM, temperature and everything you need.

Under some processor modules and expansion cards of binary and analog inputs and outputs, all programmed and configured by our team

Restoretronic, we can make the main brain of the system, the LOP5, which contains the motor controller card, in this case ECB9,

100% in all its functions.

All modules communicate with each other by means of a LOP5, DIS10, ROS7, PIM-RCS and PIM-MCS, as well as a small monitoring panel with push buttons,

visual alarms and an analogue indicator which would be mounted on the main deck of the craft.

These simulators allow us to exchange equipment we receive for repair, make communication or load tests, so that we can diagnose

failure or to check the operation of equipment after repair.

The BlueLine ECS-183 system is not as common as 2000 engines, but equipment of this type of system still enters our laboratory, so

as you see in this post we are fully prepared to solve the problems in these systems.

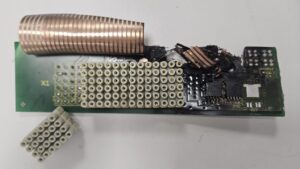

In another post I’ll show you in more depth how we serve the main board of this system, the ECB9 board.