The ECU model known as MDEC appeared on the market for electronic fuel injection control systems for MTU industrial engines in 1996. This high-performance ECU was introduced to control MTU 2000 series engines, and later to control the 4000 and 8000 series, varying in power and mechanical operating mode.

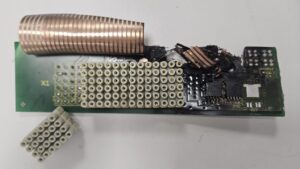

A little-known early version of MDEC was the ECU1, a control unit designed for 2000 engines known as the Seed-Sila system. This first ECU version, which featured a physical pressure sensor built into the ECU itself, was quickly replaced by the ECU4 with ECB4-01, eliminating the characteristic external oil pressure sensor attached to the ECU. It was a short transition, and few yachts currently use that first version of the MDEC ECU.

With the introduction of the MDEC ECU4, the PLD injection control system was consolidated, being installed in thousands of installations, whether marine, industrial (such as mining vehicles or trains), marine generator sets, or diverse installations such as airports, hospitals, or places with that need for power with an emergency generator.

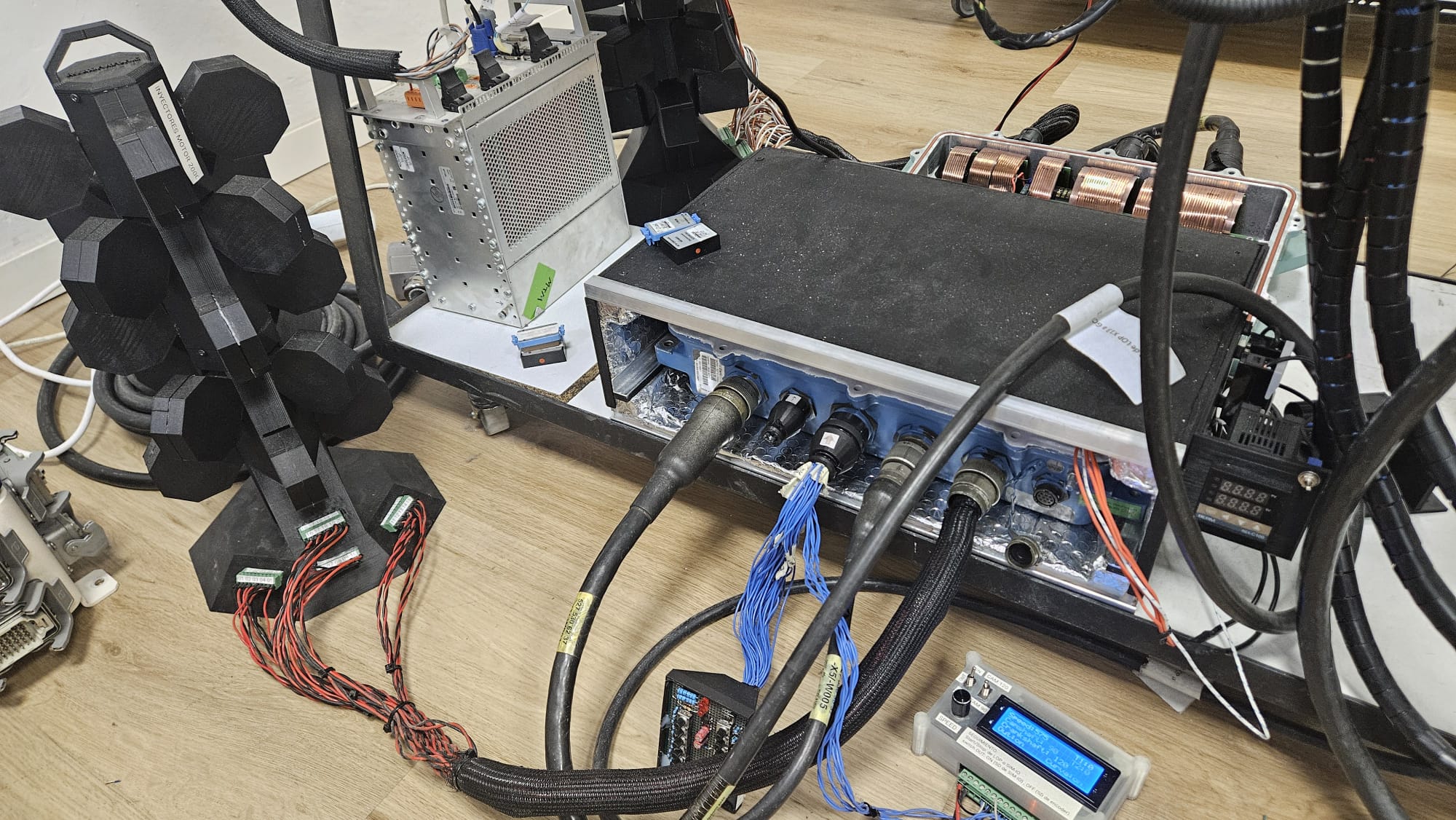

On this photo you can see part of our BlueLine simulator showing a special case to modify external temperature of ECU, all Cannon cables connected for sensors, simulating speed, temperatures, pressures, binary inputs and outputs, CAN communication and injection .

Today, we’re talking about nearly 30 years of use and applications, with recent years seeing supply issues from the MTU factory due to the obsolescence of some of the key components of this electronic unit. At Restoretronic, we’ve tested, repaired, and reconditioned hundreds of MDEC units. One of our main challenges is the simulation and emulation of all their features, creating simulators with special applications to boot the ECU and operate it in our laboratory as if it were a real installation, simulating the operation of all the necessary pressure, speed, temperature, and analog/digital input sensors, as well as the injection in its final operating stage.

These have been years of work and study on this unit, continually refining the progress of our simulators to the point where we now offer different options, with several workstations in simulators coupled with various systems such as ECS-5/MCS-5, BlueLine for the 2000/4000 series, SmartLine, or even trains or generators. All this research has led to the design and creation of this latest version of the Restoretronic simulator.

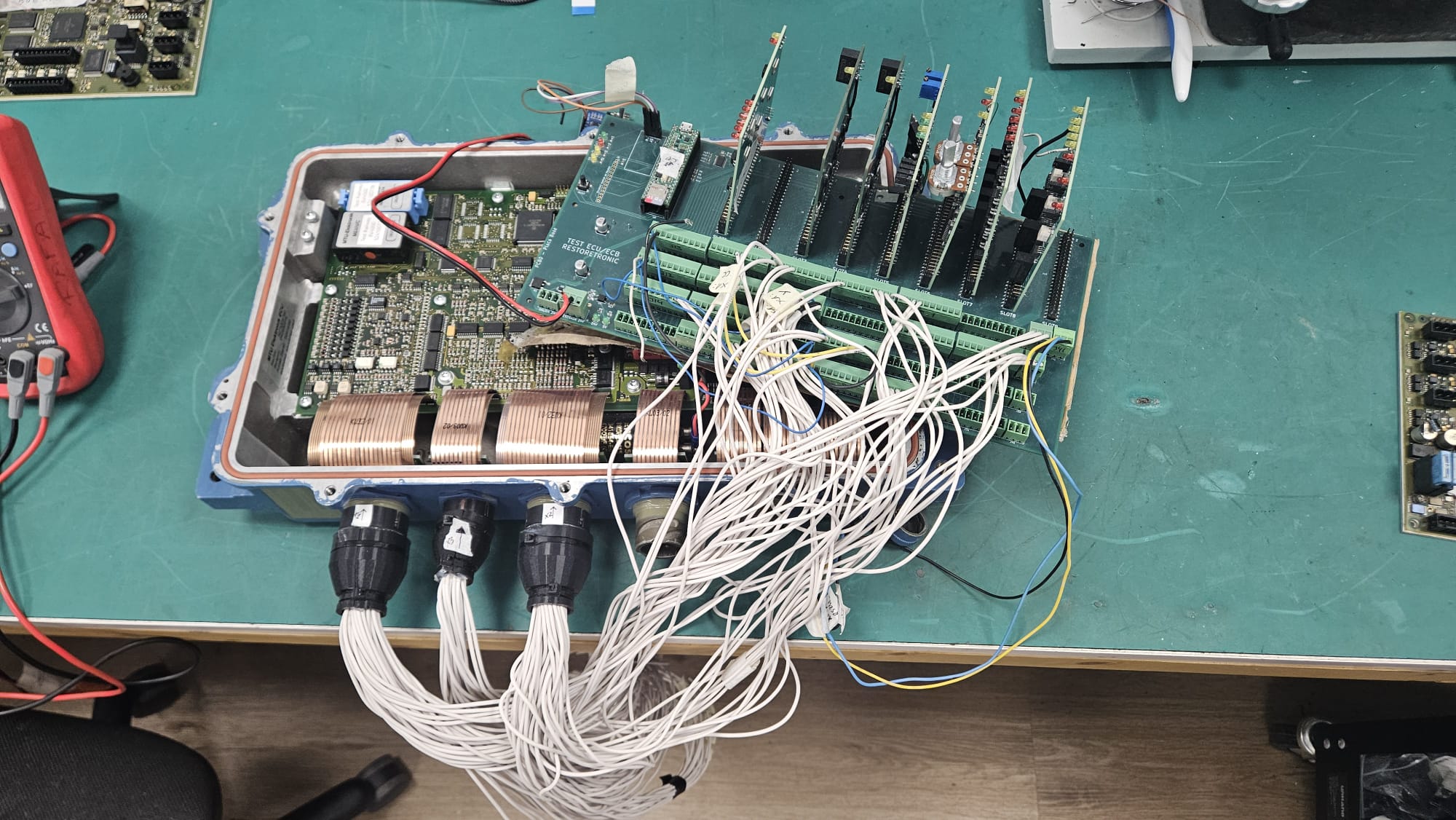

On this photo there is an ECU4 connected to a prototype of our new simulator which we will use on the bench to emulate the behavieur of an engine running.

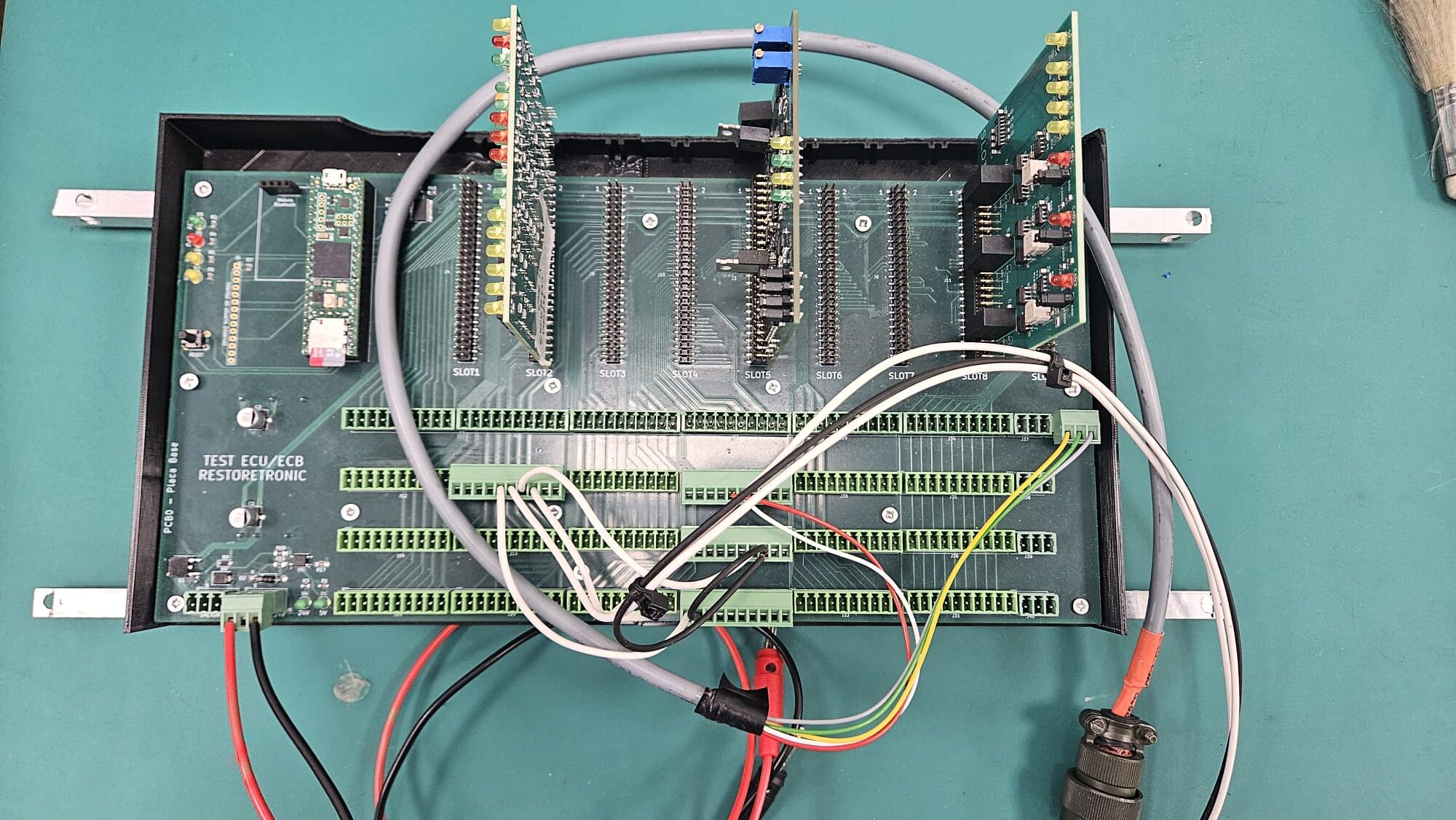

With PCBs specifically designed and created to work with MTU ECUs, not only the MDEC version but also for other ECU models associated with different engine models such as the ECU7 or the ECS-183 engine series, we have customized a test unit to be able to programmatically adapt everything necessary for each ECU model.

This is another innovation from our R&D department to be more precise and efficient in diagnosing and repairing ECUs that enter our laboratory for electronic service.